Design Process

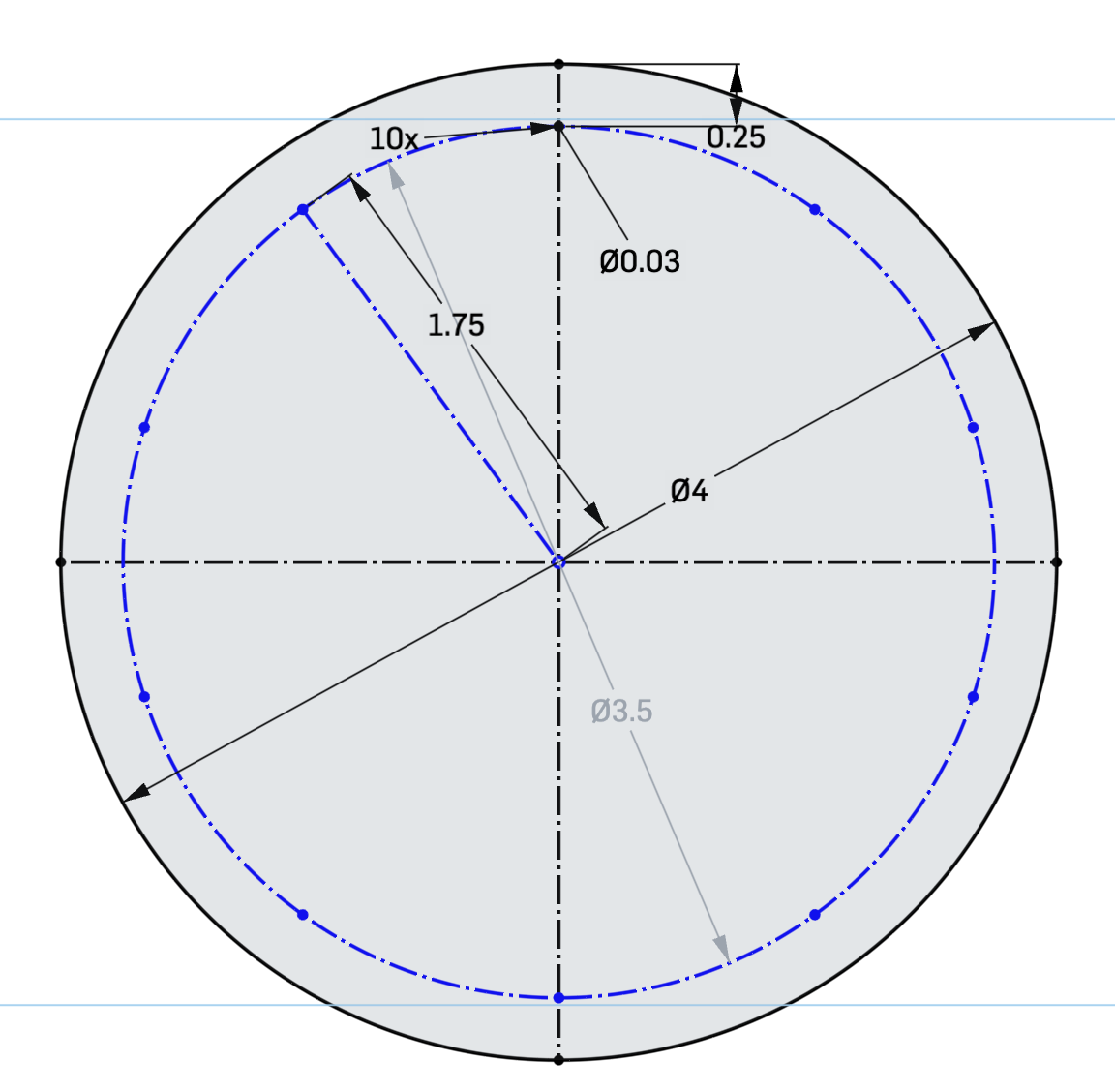

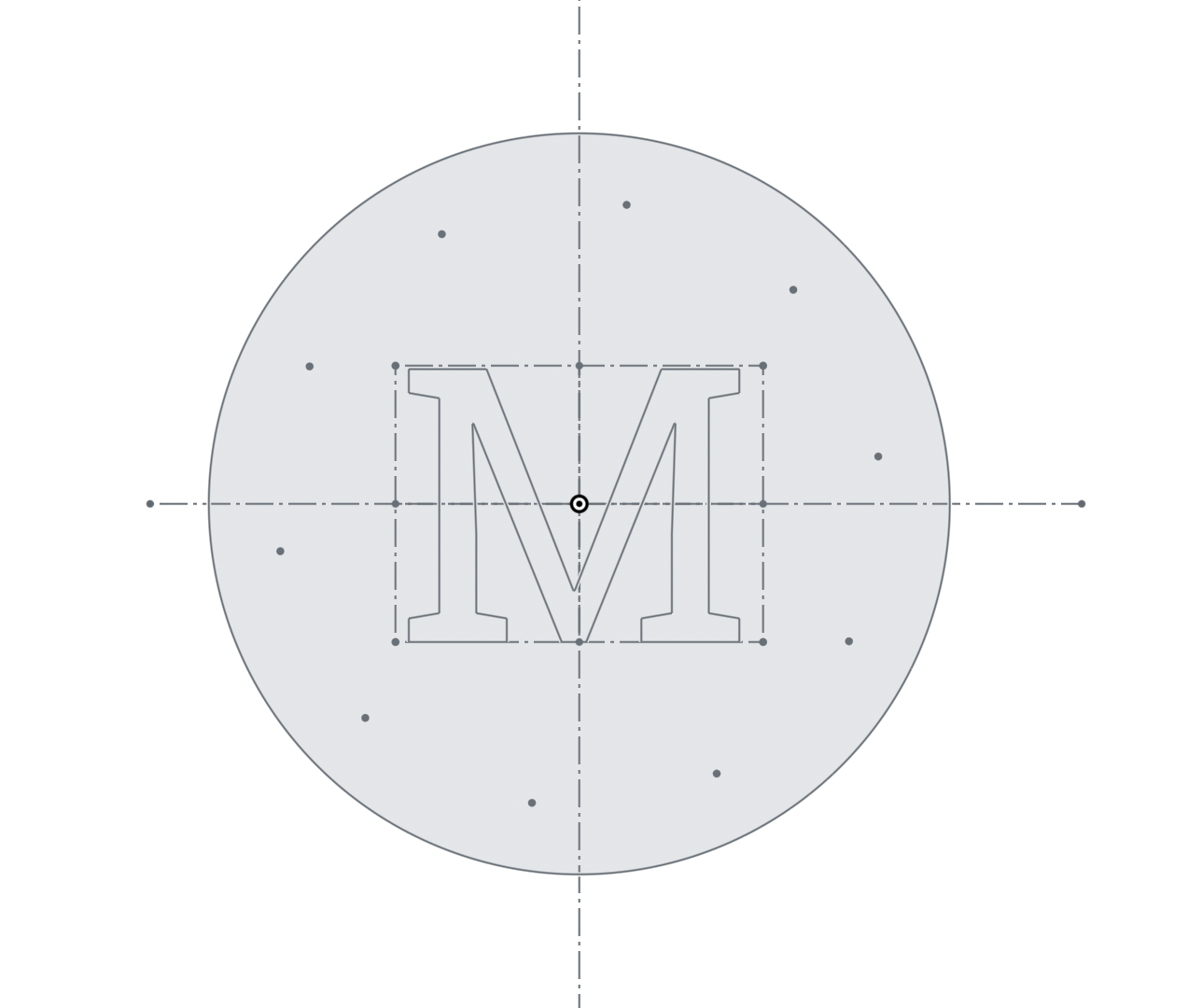

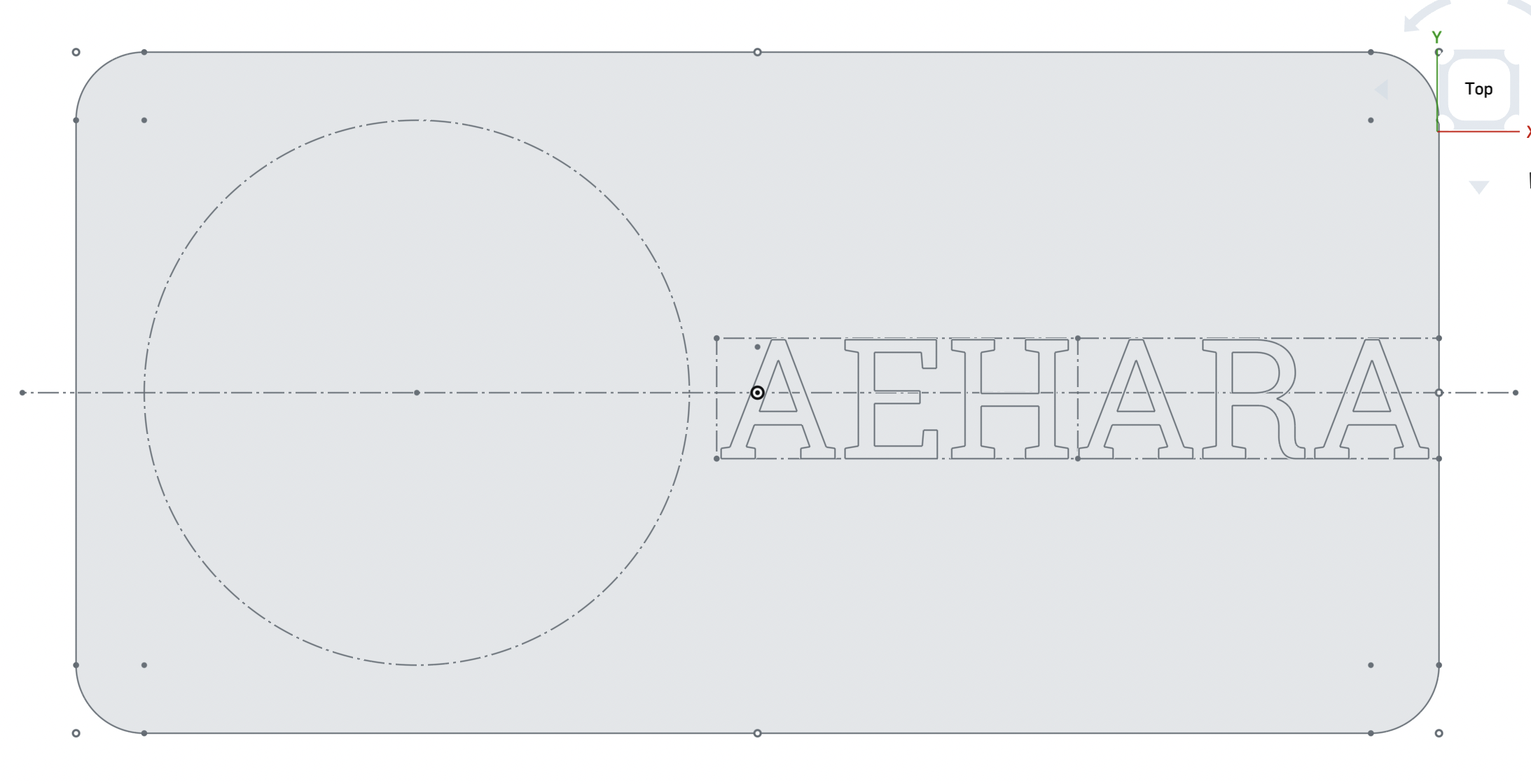

I first started off with coming up with a CAD design to be water jetted. My rivet patch was 4 inches in diameter, had 10 holes for the waterjet to pierce, and had my initial "M" in the center. I also designed a CAD file for the backplate for the patch to be riveted on with "aehara" on it. After I water jetted the patch using 1/16 thick aluminum. Afterwards I debured and drilled bigger holes to fit the rivet in the rivet gun. Lastly, using clamps we riveted the patch onto the backplate completing the project.