Design Process

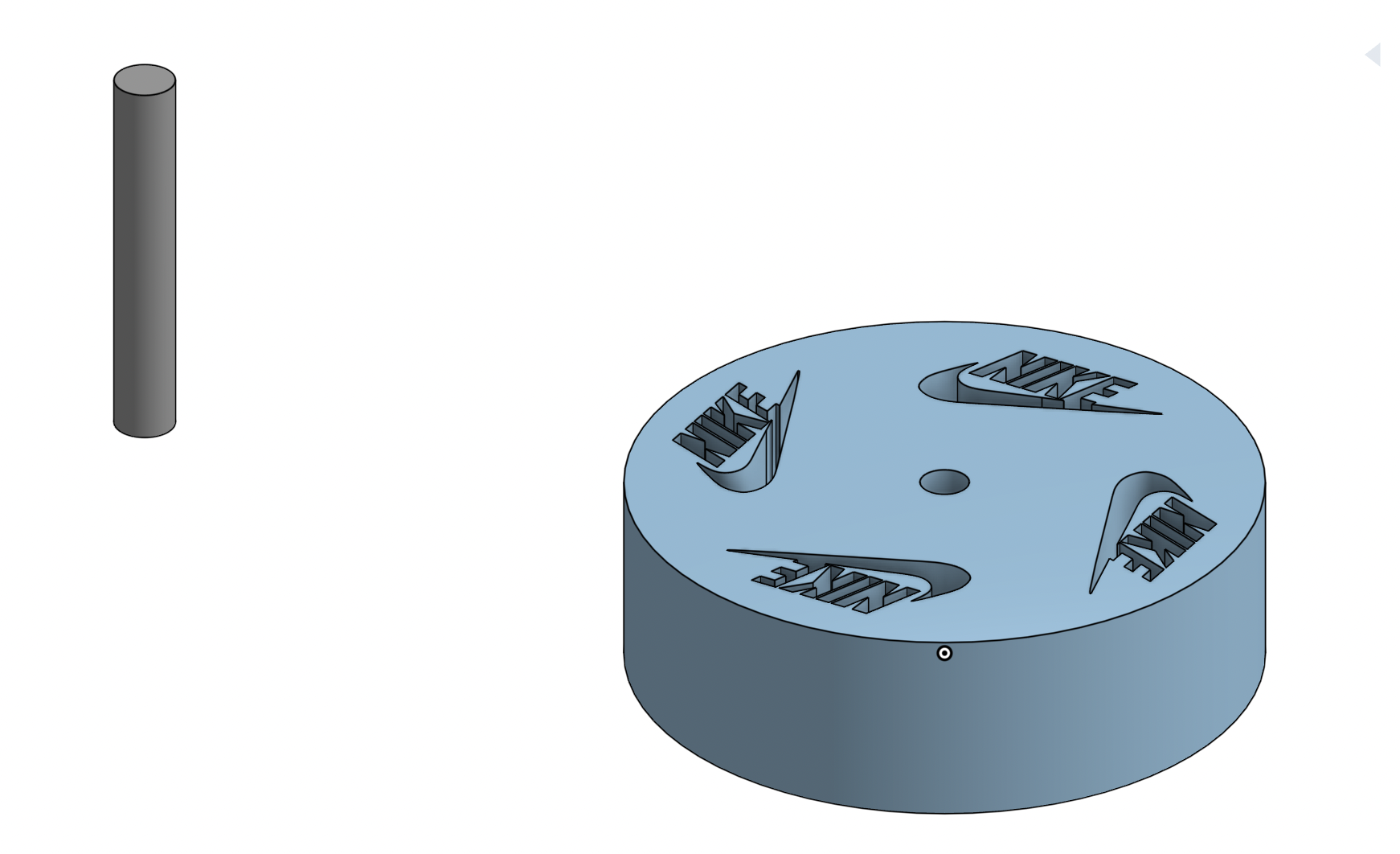

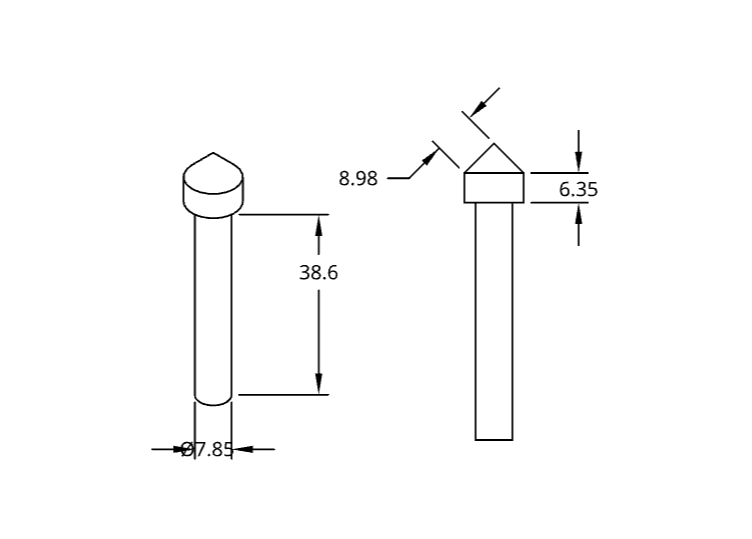

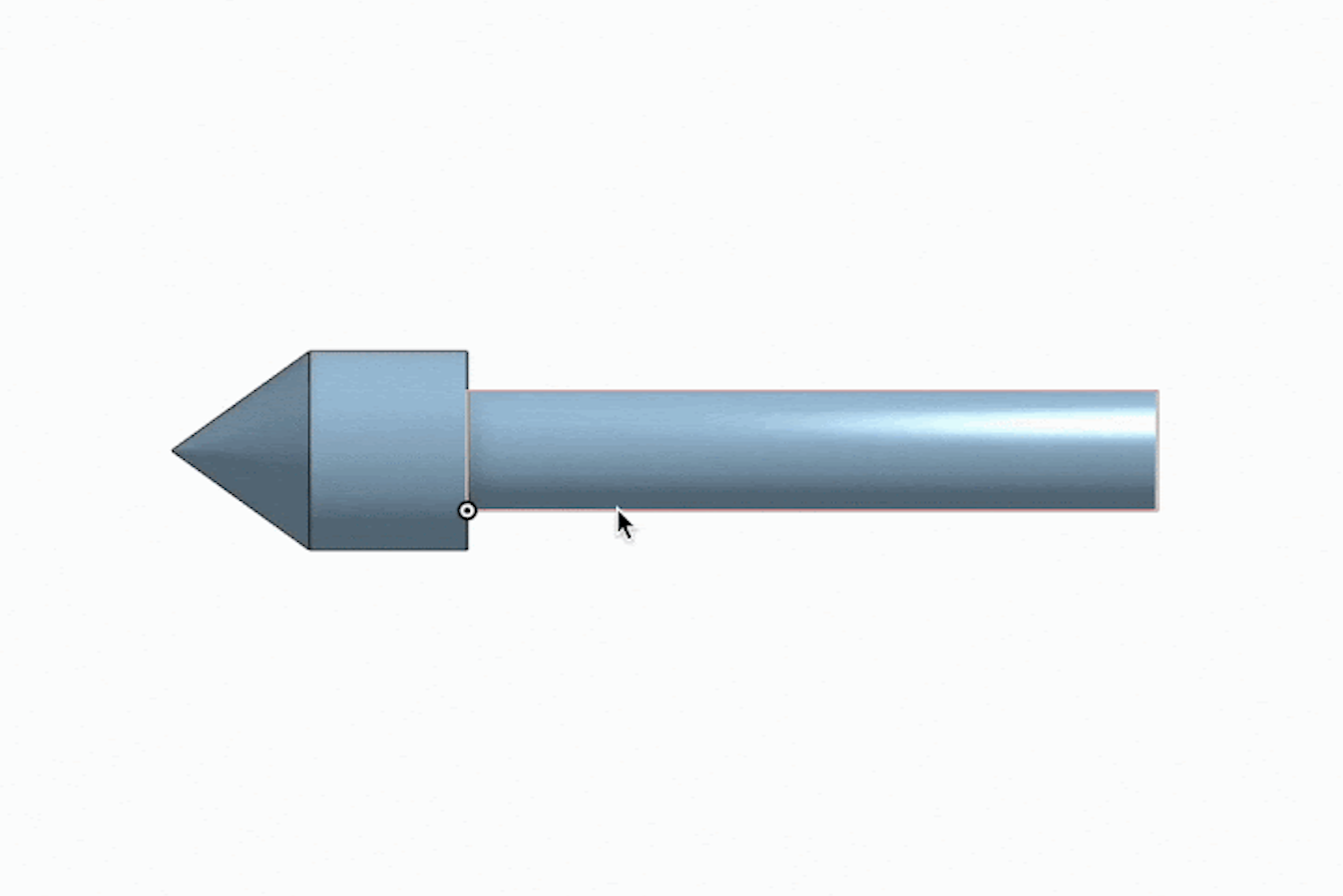

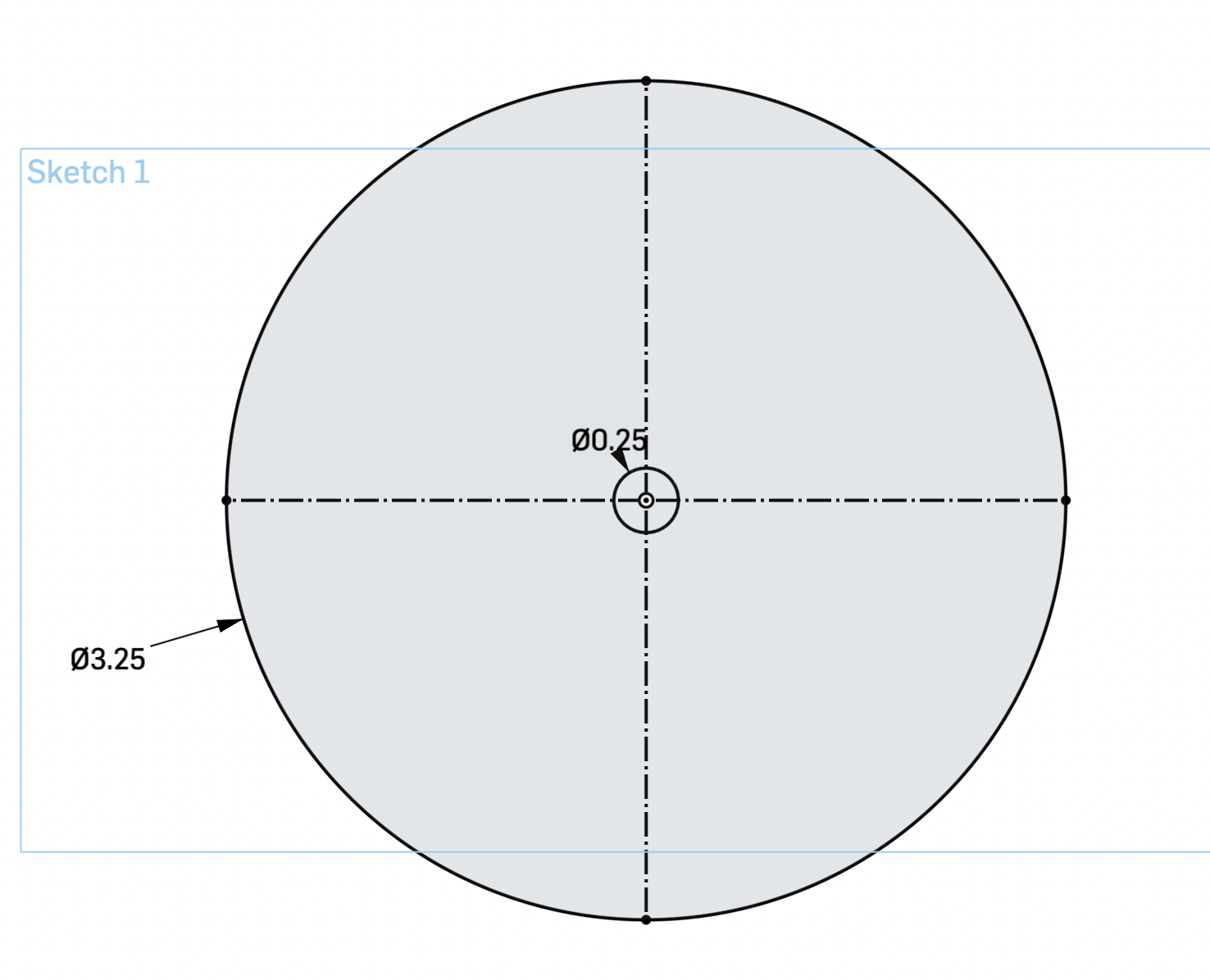

The body was a predetermined shape size of a circle with a diamter of 3.25 inches and a center diameter of .25 inches. However, we did come up with a custom pattern for the gyro that was equidistant throughout the body in order to propperly distribute weight which was cut using the water jet. The shaft however, we designed by first taking an approximate measurement using micrometers. Then, coming up with a CAD design which we then used as a reference for making the shaft. We used a band saw to cut the shaft to the predetermined size and used the lathe to shape the shaft to press fit into the bearing and bearing.